Highlights

-

•

Bio-binders are a sustainable approach to reduce the carbon footprint of paving industry.

-

•

Thermochemical conversion on biomasses is useful to obtain bio-based materials for the development of bio-binders.

-

•

Bio-binders show higher low-temperature performances than traditional bitumen.

-

•

Performance of bio-binders at high-temperatures should be improved.

-

•

A content of bio-based materials greater than 50 wt% is not commonly studied in road binders.

Abstract

Many industrial sectors exploit fossil sources to develop useful and necessary materials for our needs, such as bituminous paving materials. Bitumen, a key component of asphalt mixtures, is derived from oil refining and its properties are influenced by the crude oil source and refining process, resulting in a significant carbon footprint. With growing awareness of resource depletion and environmental concerns, pavement researchers are exploring sustainable alternatives to reduce dependence on fossil sources. This includes a rising trend in using renewable materials like biomasses to produce bio-based binders as substitutes for bitumen, aiming for a more sustainable approach. Biomasses, including vegetal and animal wastes, and waste cooking oils, as substitutes for crude oil in the production of bio-binders. Through thermochemical conversion (TCC), such as pyrolysis, biomasses can be converted into bio-char and bio-oils, which can replace fossil-based components in binders. Researchers have utilized these bio-products to reduce the dependency on fossil fuels in binders. However, there are no set minimum requirements for bio-components in bio-based binders. As the percentage of replaced bitumen increases, various types of binders are produced, including modified bitumen, extended bitumen, and alternative binders, where the fossil replacement is gradual. Overall rheological tests on bio-binders, reveal that those containing bio-char exhibit increased viscosity, stiffness, rutting resistance, and sometimes antioxidant properties. Conversely, bio-binders with bio-oils as bitumen substitutes show poorer performance at high temperatures but improved behavior at low temperatures. These results suggest that bio-binders could provide versatile solutions for various climatic and loading conditions in road construction. However, the development of pavement mixtures based on bio-binders has not been studied in depth and requires further attention to unlock its full potential. As sustainability considerations, including life cycle assessments (LCA) and life cycle cost analyses (LCC), are crucial aspects for future studies. It is essential not only to collect data on the performance characteristics of bio-binders but also to understand their environmental impact and recyclability. In-depth evaluations using methods such as LCA and LCC will provide valuable insights into the overall sustainability and long-term viability of these products.

Keywords

Biomass

Chemical process

Bitumen replacement

Bio-binder

Paving material

1. Introduction

The challenge to firstly reduce, and then nullify the dependence on fossil resources has been taken up by various industrial sectors, including the pavement industry of road transport infrastructures. Indeed, the construction and the continuous maintenance of road pavements require a large amount of non-renewable resources for the development of traditional bituminous materials. The bituminous mixture essentially consists of mineral aggregates (95 wt% approx.) and bitumen (5 wt% approx.) as a binding material. This last complex, high-molecular-weight hydrocarbon mixture, has the highest environmental and economic impacts on the construction and maintenance of transport infrastructures. Nonetheless, the production of both constituents, bitumen and aggregates, contributes to an increase in land use, greenhouse gas (GHG) emissions and other air pollution due to the extraction of non-renewable resources and the additional use of fossil-based materials during raw material processing/refining operations. Furthermore, during the production and laying processes of the bituminous mixes at temperatures between 160 °C and 200 °C, it releases toxic volatile substances that can cause damage to the operators, the environment and people (Dhasmana et al., 2023).

Eventually, researchers are investigating new bio-based materials either recycled or by-produced that could represent alternative solutions to the use of traditional bituminous binders, thus reducing the dependence on non-renewable resources (Aziz et al., 2015). Indeed, new technologies are being developed that process these materials in order to obtain valid products. Like biodiesel, which through bio-refineries, reduces dependence on fossil resources (Cooper III et al., 2013; Kazemi et al., 2022; Peralta et al., 2012a).

The approach of using new technologies is also employed for the development of more sustainable binders. In recent years, the thermal treatment of biomasses, such as pyrolysis or pyro-gasification, has achieved promising results. Indeed, a number of companies operating in this sector have carried out several studies and experimental tests for the development of bio-products using this type of thermal treatment (Gao et al., 2018). The downstream of the pyrolysis process showed similar properties to traditional bitumen, which represents a prerogative for their use in road pavements. Therefore, previous studies highlighted the suitability of using these biomaterials to reduce the fossil component of paving materials or, possibly, with appropriate improvements, to replace it completely (Wang et al., 2018; Zhang et al., 2022a). This aspect represents a strong advantage for the road industry from a sustainability point of view. Nevertheless, it is also of significant importance to understand the validity and applicability of these solutions as road construction materials.

Based on the literature review, there are several knowledge gaps that need to be overcome in order to do not limit or discourage their use by administrations and roads agencies. The main gaps can be summarized as follows (Ingrassia et al., 2019).

-

-

Aging resistance and long-term performances.

-

-

Recyclability of the bio-binder.

-

-

Health-safety-environment aspects (sustainability).

-

-

Information on the analysis of costs and effectiveness of bio-materials.

The present article summarizes the latest state-of-the-art research on bio-binders for the pavement industry. Various aspects related to the reduction of the fossil footprint in the road infrastructure sector have been considered. An overview of the potential bio-based innovative constituents of low-carbon binders and the chemical processes that they undergo for the production of suitable binder constituents have been investigated. Moreover, the potential substitution rate for petroleum bitumen based on the type of bio-material was analysed classifying the paving binders. The binders' classification may represent a crucial aspect for the development of more sustainable road construction materials and their subsequent marketing since any paving binder that contains a bio-based product, regardless its quantity, has been identified as bio-binder so far. Then, based on the completed literature review, the chemo-mechanics of the developed bio-binders and the final bio-binder mixtures were reported.

2. Bitumen and bituminous binders for road pavements

Bitumen, which is a by-product of crude oil refining, has always been used as a binding material for the production of bituminous mixtures. It is mainly a blend of hydrocarbons and these are distinguished into satures (5 wt%–15 wt%), aromatics (30 wt%–45 wt%), resins (or polar aromatics 30 wt%–45 wt%) and asphaltenes (5 wt%–20 wt%). The set of these are usually called S.A.R.A. fractions, characterized by heterocyclic species and functional groups containing sulphur (0.9 wt%–6.0 wt%), oxygen (0.4 wt%–1.0 wt%) and nitrogen (0.2 wt%–1.2 wt%). Bitumen also contains traces of heavy metals such as nickel, vanadium, iron, calcium and magnesium (Hunter et al., 2015; Lesueur, 2009). It has a thermoplastic and viscoelastic behaviour and, therefore, it is a time-temperature dependent material. Due to its thermoplastic behaviour and excellent water-repellent characteristics, it can be used in other fields rather than paving industry, mainly as a waterproofing material for exposed surfaces.

During the bituminous mixture production, the bitumen is normally heated at 150 °C–180 °C (Borinelli et al., 2020). At those temperatures, bitumen becomes a viscous liquid that can be easily pumped and mixed with the other constituents (i.e., virgin and/or recycled aggregates, fibers, chemical additives) to produce road paving materials. However, the thermal stress together with the traffic loads and severe weather conditions lead the bitumen to age in time. The main aging phenomenon of bitumen is the oxidation. In this process, the light fractions of bitumen (aromatic) evaporate with the subsequent increase of resins and asphaltene leading the material to become stiffer and brittle, which may turn into premature pavement cracking (Lesueur, 2009).

At the end of the pavement service life, the recycled aggregates coming from the milling operations of road surfaces, commonly known as reclaimed asphalt pavement (RAP), can be reused for the production of new and recycled asphalt mixtures. This type of reuse allows the exploitation of both bituminous mixtures’ constituents, i.e., aggregates and bitumen, and it is at the top of the recycling hierarchy. Nevertheless, the bituminous film that coats the recycled aggregates is aged and needs a proper restoration. By using specific chemical additivities, in terms of type and dosage, the aged bitumen can be reactivated (Hunter et al., 2015; Porto et al., 2019; Tarsi et al., 2020). This, therefore, allows a demand-reduction of additional neat and virgin bitumen leading to a more sustainable approach.

Developing more "sustainable" paving materials means making a more efficient, safe and ecological contribution, satisfying the needs of present generations without influencing subsequent generations. Thus, contributing to the green transition project by reducing energy consumption, greenhouse gas emissions (GHG), and therefore pollution. In order to continue with this challenge, reducing the dependence on neat bitumen by using recycled materials and/or by-products is essential. In this regard, based on the percentage of bitumen replacement, the developed binders can be classified as follows (Airey et al., 2008; Raouf and Williams, 2010a).

-

-

Modified bitumen, <10 wt% of bitumen replacement.

-

-

Fluxed bitumen, the bituminous fraction is replaced from 7 wt% to 15 wt%.

-

-

Extended bitumen, the bitumen substitution ranges between 25 wt% and 75 wt%.

-

-

Alternative binder, the bituminous fraction is replaced from the fossil source is between 75 wt%. and 100 wt%, often aiming to a 100% replacement.

So far, recycled materials or by-products coming from fossil origin were used to partially replace the bituminous fraction in paving materials in order to counteract the depletion of fossil and non-renewable resources but, above all, their environmental impact. Nowadays, the main interest of pavement researchers is addressed to the use of bio-based materials for the production of the so-called bio-binders in any percentage. This trend is evident in Fig. 1 that clearly shows the increased number of scientific papers on the development, production and testing of bio-based binders over time. In fact, among the total number of reviewed manuscripts, the highest quantity of studies focused on modified bio-binders. In the last decade, there was a significant growth in the research activities on bio-binders. However, these bio-binders and bio-materials used for their development still require further studies to assess their applicability as road construction materials.

Figure 1

Figure 1Several bio-based recycled materials and/or by-products from different production chains were employed as substitute of bitumen. Based on the performed literature review, the mainly used products are: swine manure, waste wood, switchgrass, oak wood, waste cooking oil (WCO), microalgae, lignin. These products were used for the production of bio-binders ascribed to all the three classes of paving binders as shown in Fig. 2.

Figure 2

Figure 22.1. Modified and fluxed bitumen

Bitumen modification, with the addition of one or more constituents, is a standard practice to change and improve the rheological properties of the base material. To achieve high road pavements durability under severe service conditions, such as temperatures and vehicle loads, bituminous binders should have a wide linear visco-elasticity range (Karlsson and Isacsson, 2006). For example, the addition of polymers either virgin or recycled, such as elastomers and plastomers, allows the improvement of the material response at high temperatures, increasing its elasticity, and also at low temperatures, reducing the resulting stiffness of the binder (Rossi et al., 2015). The polymeric material added to the bitumen absorbs the oil phase of the binder in the preparation process (temperature range 160 °C to 200 °C), forming a gel-like (cross-linked) structure. This cross-linking results in a smaller intraparticle distance and an increase in the viscosity of the binder (Lo Presti, 2013). The styrene-butadiene-styrene polymer (SBS) is commonly used as a modified agent. This is due to the excellent mechanical properties such as high fatigue resistance, elastic recovery and high resistance at extreme temperatures. It is possible to classify a large amount of various wasted elastomeric products that could be and were employed as constituent material for bitumen modification (Airey, 2004). For example, the rubber from end-of-life tyres (ELTs) is a high valued product that can be further exploited after the tyres’ service life. Furthermore, the use of these waste materials entails a double benefit, the improvement of the performance of the bitumen and the possibility of recycling materials. Therefore, modification of bitumen using crumb rubber presents itself as a sustainable approach (Ibrahim et al., 2013).

Several studies also reported the use of bio-polymers for the modification of bitumen, including poly (lactic) acid (PLA). PLA is a bio-based green thermoplastic polyester obtained from sugar cane or corn-starch; these elements can be easily found in plant biomasses (Auras et al., 2004; Rasal et al., 2010). The presence of carboxyl and hydroxyl groups within its structure allows the development of chemical reactions with the bitumen, defining its compatibility. Moreover, this bio-polymer is an interesting candidate for replacing traditional polymers, due to its high tensile strength and high modulus. Indeed, the mechanical tests conducted on bitumen modified with PLA (<10 wt%) showed good results in terms of hardness, stiffness and ductility (Jailani et al., 2021).

The bitumen modification can be also carried out with bio-chars aiming to improve the binder properties. Bio-char is another product of thermochemical conversion processes. It comes in the solid form and it is rich in carbon, but it also contains nitrogen, hydrogen and traces of heavy metals (Rondón-Quintana et al., 2022). Before being added to the binder mixture, it is reduced to particles of the order of μm (75–150 μm) and subsequently added to the bitumen. The bio-char content in bitumen varies in a range between 2 wt% and 20 wt%, nevertheless studies have shown that 10% by weight may represent the optimal content (Walters et al., 2015; Zhao et al., 2014a). Finally, a bitumen modified with bio-char has been proven to provide a higher resistance to permanent deformation (rutting), a better resistance to aging and also higher viscosity (Zhang et al., 2022a).

In order to reduce the stiffness of the final bituminous binders specific chemical additives could be also incorporated in the bitumen as fluxing or rejuvenating agents. Nowadays, due to the increased approach to the recyclability of RAP, several chemical additives with rejuvenating properties are employed as a partial substitution for neat bitumen. Different types of products either bio-based or fossil-based can partially, or almost fully restore the properties of the bitumen, such as oleic acids, or linoleic acids (Cao et al., 2019). The use of biological materials is growing rapidly because, if treated with thermochemical conversion processes, they can positively influence the properties of the bitumen. Following this approach, it was determined that 2.5% of rejuvenator by weight, in the RAP, gives a mixture development with properties comparable to those of a mixture with fresh bitumen (Barzegari and Solaimanian, 2020). In particular, these properties are attributed to the presence of amine and amide groups within the composition of bio-oils. Formulations containing bio-oils with these groups can be characterized as self-rejuvenating bio-binders, as they exhibit greater durability and resilience to aging, extending the life of various infrastructure applications such as road pavements (Kazemi et al., 2022, 2021).

The natural compounds derived from biomass that are incorporated in bitumen need to be previously converted into oils (bio-oils). Among the materials widely used, of natural origin, as bitumen modifiers are WCO and swine manure. Studies on bio-oils obtained from swine manure, if used to replace bitumen, with percentages of approximately 5% by weight of the total blend, allow an improvement in properties. This percentage can improve the low-temperature cracking properties and confers a decrease in the viscosity of the bitumen (Fini et al., 2012). In addition to the performance advantages of the mixtures, life cycle assessment (LCA) studies demonstrate that substituting fossil components with bio-oils has the potential to significantly decrease both energy consumption and global warming impact. This reduction is attributed to the diminished release of pollutants associated with bio-oil utilization, highlighting its environmental and sustainable benefits (Kazemi et al., 2022; Samieadel et al., 2018).

2.2. Extended bitumen and alternative binders

Increasing the percentage of bitumen substitution above 25 wt% and up to 75 wt% the resulting bituminous binders are commonly known as extended bitumen. The extenders should therefore replace a significant portion of the traditional bituminous binders. Thus, if modifiers would enhance the final performance of a base binder, the extenders should at least replicate the physio-mechanical response of traditional paving binders (Dhasmana et al., 2023; Yang et al., 2015). This substitution usually contributes to the sustainability of the final material. In order to limit the consumption of fossil sources, and the related issues, a possible material proposed for the extension of bitumen is lignin. Several studies were conducted on lignin by the federal highway administration (FHWA) demonstrating the feasible use of the material as a replacement of bitumen fraction, but also as an additive for the improvement of the binder’s properties. Lignin not only acts on the physio-mechanical response of the extended bitumens, it also has an antioxidant effect, therefore it counteracts the aging phenomenon (Pérez et al., 2019; Sun et al., 2017). However, the use of lignin alone does not allow the development of full alternative binders. In fact, during the preparation of the extended bitumen, high percentages of lignin may lead to the formation of foam and crystallization of the material, which limit the maximum percentage of the substitution (Xu et al., 2017).

Striving to the green transition of the paving sector, the studies on more sustainable bituminous binders have been intensified in recent years to make the fraction of standard bitumen within the binders even smaller. Researchers are committed to developing binders, where the fossil contribution is lower than 25 wt% aiming to zero. The materials that contain a very small amount or no quantity of bitumen are called alternative binders. Usually, the replacement takes place with waste materials, which can be of natural origin, both vegetal and animal, but also municipal wastes, to give them a second life and minimize their disposal in landfills (Aziz et al., 2016).

Today, in the pavement industry sector, the term bio-binders has reached a great level of attention. Indeed, it is meant as a binding material that is formulated in the presence of material from biological sources, in particular biomass. Therefore, all the classes of binders described above, being formulated with materials of biological origin, fall into the group of bio-binders with no recognized threshold value.

3. Feedstock: renewable materials

The raw materials that may be used as constituents of road construction materials must follow both ecology and economy criteria at the same time (Seidel and Haddock, 2012). For example, either the reuse or the recycling of end-of-life/waste materials, preventing their disposal into landfills, represents a valid solution since they meet both criteria. Furthermore, the recyclability concept should be applied to the existing pavements, and hence, to the bituminous mixes already produced and in service. Recyclability is an already known property of bitumen, therefore a new-generation binder, such as bio-binders, must possess this characteristic. From the point of view of the economic criterion, however, there is a need for the high availability of the material in the area, or its ability to renew itself, as the biomasses.

Among the available bio-based raw materials, biomasses are often an excellent resource due to their high continuous availability so that they can be considered as renewable. A biomass is any organic substance, either vegetal or animal, available on a renewable basis. The annual world production of biomasses is approximately 200 billion tonnes, of which, to date, only 30% is used for various types of applications. Among the several applications of biomasses, the production of bio-fuels and chemicals can be highlighted (Pasquale et al., 2012). Being rich in carbon, these products can be identified as a possible substitute for crude oil. Within the domain of biomass, it is possible to find a high quantity of substances: vegetation waste, agricultural waste, municipal solid waste, animal waste, food processing waste, aquatic plants and algae (Demirbaş, 2001). This domain can be divided into biomasses that have a low and a high moisture content, i.e., dry biomasses (mainly lignocellulosic materials from wood of forest origin, solid organic waste, etc.) and wet biomasses (slurry, food waste, etc.). Depending on the type of used biomasses, the waste products should follow different thermal treatment processes: dry biomasses usually undergo a pyrolysis process, while wet biomasses are subject to hydrothermal liquefaction (HTL) process (Weir et al., 2022). From these processes, three products can be normally obtained (Barik, 2019; Graham et al., 1984).

-

-

Bio-oils.

-

-

Bio-chars.

-

-

Non-condensable gases.

According to the rate of the thermal process, different percentages of each of the three products are obtained (i.e., fast rate of the process, high amount of bio-oil). The biomasses converted into bio-oils mainly derive from agricultural residues, animal residues and algae (Demirbaş, 2009; Dhasmana et al., 2015). Indeed, it has been demonstrated that raw materials such as oak wood, tall oil from pine, switchgrass and microalgae, based on the knowledge acquired on the properties and composition (mainly from sugars, proteins and starch) are suitable for producing bio-binders for the paving sector. The application of these raw materials showed high performances as a replacement of the traditional bitumen at percentages equal or above 25 wt%, i.e., production of extended binders, and also alternative binders (Airey and Mohammed, 2008; Cooper III et al., 2013; Geantet et al., 2022; Peralta et al., 2012a; Raouf and Williams, 2010b).

Other types of raw materials that are not classified as biomasses, but are collected from biological sources, are WCOs, i.e., the exhausted vegetable oils used for cooking. There are many vegetal sources from which they can be obtained. The basic materials are lipids of vegetable origin such as margarine, butter, olive oil, corn oil, sunflower oil, etc. (Dizge et al., 2009). They are necessarily classified as renewable sources given their high availability worldwide (Presidente Della Repubblica, 2011). It has been estimated that more than 15 million tonnes of waste cooking oils are produced worldwide annually and in Europe, the amount produced is around 1 million tonnes (Mannu et al., 2019). Of these enormous quantities, fuels such as bio-diesel are developed through new technologies and catalytic processes (Yaakob et al., 2013).

4. Treatment processes of the renewable biological resources for bio binders

As anticipated, bio-binders are defined as a paving binder where a variable portion of bitumen has been replaced by a biological and renewable resource. In order to develop a suitable bio-binder formulation, the biomasses are subjected to thermal treatment processes. It basically refers to a family of processes that all fall under thermochemical conversion (TCC). TCC is a chemical reforming in which depolymerization reactions of the reactants take place inside a heated and oxygen-free reactor. The characteristics of the products obtained depend on that of the starting material (He et al., 2000). Thermochemical conversion technologies differ according to the oxidation environment, particle size, heating rate and type of heating, in the absence of oxygen, endothermic, ΔrH > 0, (where ΔrH represents the change in enthalpy, indicating the heat absorbed, >0, or released, <0, during a reaction at constant pressure) or complete oxidation, exothermic, ΔrH < 0, of the reactants (Tanger et al., 2013). The TCC process is often divided into three subcategories (Damartzis and Zabaniotou, 2011).

-

-

Combustion.

-

-

Gasification.

-

-

Pyrolysis.

The biomasses treated by the combustion process generate heat (energy) due to the oxidation reaction, where carbon, hydrogen, oxygen, combustible sulphur and nitrogen react with air or oxygen. Combustion is the most common way of converting biomasses into usable thermal energy (Bhaskar et al., 2011). The gasification process consists of the conversion of solid material into combustible gases or into synthesis gas (syngas). If applied at biomasses, this process leads to the conversion of carbonaceous compounds into combustible gas with specific calorific values (heat of combustion) in the presence of oxygen. The oxygen used in gasification leads to partial combustion of the material. Furthermore, it has a low environmental impact due to low toxic gas emissions and the management of solid by-products (Kirubakaran et al., 2009). Finally, the pyrolysis process is used for the development of bio-oils. It consists of the application of heat in the complete absence of an oxidizing agent (i.e., oxygen). Different types of pyrolysis can be used for the development of bio-oils. The most widely used are fast pyrolysis (FasP) and hydrothermal liquefaction (HTL) where the latter is also called hydrated pyrolysis. According to the literature, based on the type of biomass, different types of processes are applied, as listed in Table 1.

| Reference | Type | Biomass | Process | Condition |

|---|---|---|---|---|

| Peralta et al., 2012b | Waste wood | Red oak | FasP/pyrolysis | τ ≅ 400 s, T = 500 °C, bio-oil yield = 60.0% |

| Ciuta et al., 2014 | Sugarcane bagasse | FasP | τ ≅ 120 s, T = 560 °C,bio-oil yield = 53.4% | |

| Ciuta et al., 2014 | Palm empty fruit banch | FasP | τ ≅ 60 s, T =540 °C,bio-oil yield = 48.0% | |

| Abnisa et al., 2011 | Palm shell | Pyrolysis | τ = 60 min, T=500 °C,bio-oil yield = 47.0% | |

| Raouf and Williams, 2010b | Oakwood, witchgrass, corn stover | FasP | τ < 2 s, T = 480 °C,bio-oil yield = 60.0% | |

| Fini et al., 2011 | Animal manure | Swine manure | Pyrolysis | τ = 80 min, T = 304 °C,bio-oil yield = 60.0% |

| Mills-Beale et al., 2014 | Swine manure | Pyrolysis | τ = 80 min, T = 380 °C,bio-oil yield = 70.0% | |

| Wang et al., 2020 | Swine manure | Pyrolysis | τ ≅ 1 s, T = 550 °C,bio-oil yield = 45.1% | |

| Vardon et al., 2011 | Swine manure | HTL | τ = 30 min, T = 300 °C,bio-oil yield = 30.0% | |

| Vardon et al., 2011 | Algae | Spirulina algae | HTL | τ = 30 min, T = 300 °C,bio-oil yield = 30.0% |

| Audo et al., 2015 | Microalgae | HTL | τ = 60 min, T = 260 °C,bio-oil yield = 55.0% |

Note: τ is the reaction time.

4.1. Pyrolysis

Pyrolysis is one of the most promising TCC processes and plays an important role in biomass conversion. However, the pyrolysis process is very complex because a different path is followed based on the type of component being processed (Yang et al., 2007). The pyrolysis products mainly depend on the temperature and heating rate. They occur, in different percentages by weight, in all three states of aggregation: non-condensable gases (e.g., CO, CO2), a liquid obtained from the condensation of gases (hydrocarbons and water) and finally the solid fraction, given by char (coal and ashes). Depending on the desired product, it is possible to carry out different types of pyrolysis. The goal is to obtain material from biological sources that can be used in the production of paving compounds. Indeed, depending on the type of desired product, it is possible to enrich the different fractions by modifying the process conditions. For example, to maximize the amount of char, hence of the solid fraction, the heat is transferred to the sample more slowly. In this case, the so called slow pyrolysis is adopted (Hernandez-Mena et al., 2014). If instead, the desired product is the fraction of condensable gases (bio-oils) as in the case of the paving industry, the heating rate is very high, and the fast pyrolysis is applied (Graham et al., 1984).

It is possible to divide the pyrolysis process into several phases, which are related to the different temperatures encountered during the process. The initial phase of the process is defined as drying (≃100 °C) that is a preliminary phase. The temperatures are lower and in this first part, the humidity and any present water are removed. After drying, another phase starts between 100 °C and 300 °C, where the dehydration of the biomass takes place allowing the removal of further low molecular weight molecules such as CO2 and CO. This is followed by the intermediate phase where temperatures range from 200 °C to 600 °C. Condensable vapours are generated, from which bio-oils and incondensable gases are obtained and the biomass begins to transform into a primary char. Eventually, the final phase (≃300 °C-900 °C). If the vapours that develop reside for a sufficiently long time inside the biomass, the formation of secondary char and further incondensable gases is generated. The formation of these is given by the cracking of the species that have vaporized (Basu, 2018; Boateng, 2020; Diebold and Bridgwater, 1997).

The most relevant pyrolysis process for paving applications is the FasP. During the FasP the heating time is much shorter than the reaction time, indeed, the generated vapours remain inside the reaction system for a few seconds (Graham et al., 1984). These conditions allow for the maximization of the production of condensable gases by avoiding secondary reactions such as the cracking of larger molecules into non-condensable gases. With this type of process, the percentage of bio-oil obtained varies in a range between 60%-75% by weight. The other products obtained are incondensable gases and solids, char, in which the percentage ranges of these by-products are respectively 10%–20% by weight (gases) and 15%–25% by weight (solids) (Barik, 2019; Jiang et al., 2016). The biomass heating rates are very high, approximately equal to 200 °C/s, with maximum temperatures ranging from 450 °C to 750 °C (Safdari et al., 2019).

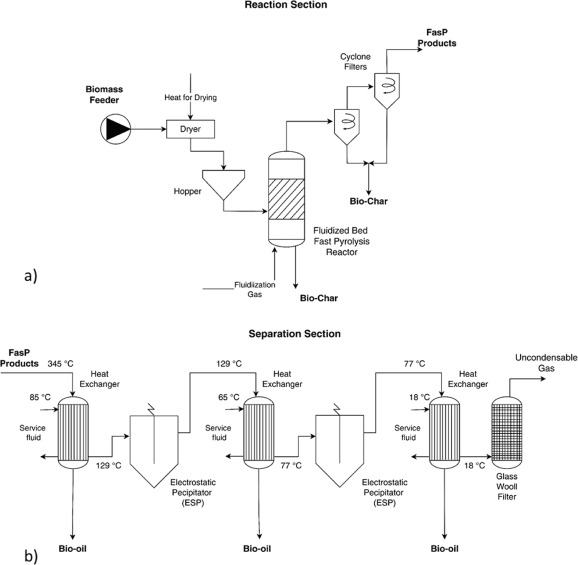

The fast pyrolysis process for the production of bio-oils was carried out using different types of technologies. Peralta et al. (2012b) have developed a pilot plant (at the Iowa State University) consisting of a fluidized bed reactor (Fig. 3(a) and (b)). The use of this type of plant is able to process about 10 kg/h of biomass converting it up to 70 wt% of the resulting bio-oil with an operating temperature of 450 °C. The study was conducted by processing organic biomasses, mainly of plant nature, such as red oak wood, switchgrass and corn stover. These are lignocellulosic biomasses, made up of bio-polymers such as cellulose, hemicellulose and lignin (Greenhalf et al., 2013). The same system configuration was also adopted using wood previously treated in the laboratory with preservatives. These compounds would have preventive action against the attack, for example, of fungi. These preservatives are inorganic complexes of metals such as copper, chromium and boron. Downstream of the fast pyrolysis process, the metals content is very low in the oily fraction, while it is high in the solid one (bio-char). Thanks to this analysis, the effectively of the fast pyrolysis to treat contaminated lignocellulosic biomasses has been understood. Hence, a wide variability of vegetable biomasses can be used in this process. The obtained bio-oils, purified from traces of heavy metals, can still be used for the development of further products. Previous studies also focused on empty fruit bunches (EFB). The reactor configuration adopted is that of a fluidized bed reactor. Studies on the bio-oils produced by EFB fast pyrolysis was carried out at different temperatures (400 °C, 500 °C, 600 °C). EFBs have been shown to be well-pyrolyzed. Furthermore, maximum yields of bio-oils were obtained at temperatures close to 450 °C (Ciuta et al., 2014; Sembiring et al., 2015). The fast pyrolysis can be carried out in production plants that exploit fluidized bed reactor, which is the most used application, and the ablative one. In ablative plants, the heat is transferred by conduction to the biomasses, which are subjected to a rotating movement and high pressures (about 50 bar) (Peacocke, 1996). The high operating conditions allow to prevent the possible condensation of the produced high-boiling products. The bio-char obtained is removed by gravity; while the developed gases are condensed to obtain bio-oils. Auersvald et al. (2020) tested ablative pyrolysis with different types of lignocellulosic biomass (beech wood, poplar wood, straw and miscanthus). The obtained results from fast ablative pyrolysis were found to be comparable to those of a fluidized bed reactor. Indeed, the obtained liquid phase yields are very close between the two configurations, around 60 wt%. Among the quantity of obtained liquid phase, a fraction consists of water, which is in greater quantity in the case of straw and miscanthus. The limited use of this type of technique is given to the high operating and production costs. However, there are other limitations related to the fast pyrolysis process in general. The composition of the bio-oil has a high content of oxygenated compounds and water, that turn into a highly viscous, corrosive mixture capable of damaging the equipment in which it is contained (Auersvald et al., 2020; Bridgwater et al., 1999; Greenhalf et al., 2013; Mohan et al., 2006; Peacocke, 1996; Peralta et al., 2012a, b; Sembiring et al., 2015).

Figure 3

Figure 34.2. Hydrothermal liquefaction

Another TCC process widely studied by researchers for the production of bio-oils and their subsequent applications is the so-called HTL or hydrated pyrolysis. The HTL process is a thermochemical depolymerization process where the reactor converts the wet biomasses under more moderate conditions than the fast pyrolysis; in fact, in the HTL temperatures vary between 200 °C and 400 °C and pressures are variable in the 10-25 MPa range (Zhang and Chen, 2018). The process tries to simulate natural degradation that converts dead plants and living matter buried underground into possible fuels. Furthermore, given the quantity of water present in the biomasses, the HTL acts as a reaction medium for the development of the products (Dhasmana et al., 2015). Fini et al. (2011) applied the HTL process to pig manure. The starting material is loaded into the mixed reactor (continuous stirred tank reactor CSTR) at 300 °C. The whole system is kept under pressure thanks to a current of nitrogen at 10.3 MPa for removing the residual air. Upon completion of the reaction, the system is rapidly cooled. The process produces gases that are condensed into bio-oils and a viscous residue. Differently than fast pyrolysis process, where the bio-oils are used for the development of the bio-binders, in the application of HTL process on swine manure, the residue is used for their development. In general, the bio-binders that has been developed using this bio-source fall into the class of modified bitumen. Hence, it was used in a limited quantity with the aim of improving the rheological properties of the starting binder (Bridgwater et al., 1999; Fini et al., 2011; Oldham et al., 2015). Other HTL processed biomass products that exhibited good properties for the development of bio-binders are obtained from microalgae. Indeed, it has been determined that it is possible to obtain similar properties to those of bitumen from the residues of processed microalgae. The application of the process on microalgae, in particular Scenedesmus species, has been extensively studied by catalysing the HTL process. Among these (Geantet et al., 2022), compared the performance of the products obtained from the HTL processes with and without a catalyst. The use of catalysts allows the modification of the viscosity and rheology of the final product, since it uses cerium nitrate hydrate, Ce(NO3)2∙6H2O, which leads to a growth of the molecules such as longer-chains hydrocarbons. The product obtained from the catalytic process showed good performance. Indeed, the properties of the final material exhibited similar stiffening and rheological properties to those of bitumen, which were better replicated in respect to the products of non-catalytic process. Thus microalgae can be used to develop alternative binders in which the bitumen content is zero (Elliott et al., 2015; Geantet et al., 2022; Maag et al., 2018).

5. Developed bio-binders

The use of bio-materials (bio-oils, bio-char) does not envisage a direct use in the development of bituminous binders either extended or alternative, which can be subsequently used as bitumen replacement in paving admixtures. The products obtained from TCC processes are characterized by relatively low viscosity values, typical of bio-oils, therefore preliminary treatments are necessary. The low viscosity of bio-oils is due to the presence of water and volatile compounds in the products. To remove these light fractions, thermal pre-treatments was found in the literature. The thermal process consists of heating the bio-materials while monitoring their viscosity. The materials are exposed to high temperatures, which vary from 120 °C to 140 °C, for 8 h (Raouf et al., 2010). In case of any experienced difficulties in the light fractions’ removal, due to the boiling temperatures of the components, a vacuum distillation is required. With this method, the light compounds are completely removed. In the event that distillation processes for the removal of light fractions are not effective, it is possible to use polymers that can increase their viscosity. Polymer modification is a method that is carried out to obtain bio-binder with further enhanced properties. Styrene-butadiene-styrene (SBS), polyethylene (PE), and powdered rubber are already widely used in the field of high-performance bituminous binders (Pyshyev et al., 2016). Given their well-known functionality, they are also adopted for the modification of bio-materials. In this regard, the modifications with polymeric materials of bio-materials still need in-depth studies (Fini et al., 2012; Mateus et al., 2016; Peralta et al., 2012b; Zhang et al., 2022a).

In most cases, the development of bio-binders requires the interaction of bio-materials with bitumen. Given the various types of constituent materials available in the market, it is important to understand their behaviour when mixed with bitumen. In general, if the bio-materials are in a solid phase, they are often used as a modifier of the blend, in fact, the percentages are <10 wt%. The bio-char, for example, is added in small percentages to implement properties such as viscosity, permanent deformation at high service temperatures, and resistance to aging (Rondón-Quintana et al., 2022; Zhao et al., 2014b). During the preparation process, using solid bio-materials, such as bio-char, in order to achieve the homogeneity of the mixture, more sustained conditions in terms of agitation and temperature are necessary (e.g., 120 °C–160 °C at 2000-5000 rpm for one hour) (Ingrassia et al., 2019; Rondón-Quintana et al., 2022; Zhang et al., 2022b; Zhou et al., 2020; Zhou and Adhikari, 2019). The prolonged action of mixing time and temperature could lead to changes in the structure of the binder and to aging processes. The use of bio-char within the binding mixture has a verified counteracting action against aging. In fact, bio-char slows down oxidation and reduces the volatilization of the light compounds present in the binder (Dong et al., 2020).

Differently, bio-binders can be produced using bio-oils that may have different functions. For example, bio-oils may soften a hard bitumen or an aged one, exhibiting a fluxing or a rejuvenating effects (Jiménez del Barco Carrión et al., 2017; Ingrassia et al., 2019; Sun et al., 2016). It is possible to use bio-oils which, after the treatment processes described above, have similar bitumen-like characteristics. In this case, their use, within the formulation, allows for a substantial replacement of this fossil source. Hence they can be employed as a significant replacement of bitumen (Ingrassia et al., 2019). In this regard, for the interactions between standard bitumen and bio-source it is crucial to properly define and characterize the bio-binder, because the structure of the bitumen always influences its performance. Indeed, studies conducted on the preparation of bio-binders with bio-oils report different process conditions, due to the different affinities with bitumen. Table 2 shows the different process conditions for the preparation of bio-binders with bio-oils obtained from different types of biomasses. The addition of a biological component to the bituminous mixture, given the differences in terms of chemical composition, could lead to reactions.

| Reference | Biomass | T (°C) | t (min) | Mix rate (rpm) |

|---|---|---|---|---|

| Raouf and Williams, 2009 | Sawdust, corn stalks | 110 | 30 | 6000 |

| Yang et al., 2014 | Waste wood | 120 | 20 | 5000 |

| Zhang and Chen, 2018 | Waste wood | 130 | 20 | 5000 |

| Gaudenzi et al., 2022 | Waste wood | 180 | 30 | 5000 |

| Gao et al., 2018 | Sawdust | 120 | 20 | 1000 |

| Gong et al., 2016 | Waste cooking oil | 130 | 10 | 3000 |

| Sun et al., 2016 | Waste cooking oil | 170 | 30 | 4000 |

| Onochie et al., 2013 | Swine manure | 120 | 30 | 1600 |

| Fini et al., 2011 | Swine manure | 200 | 30 | 1000 |

| Hill et al., 2013 | Swine manure | 135 | 30 | 1800 |

Several studies reported chemical analyses on bitumen and biological components by means of Fourier transform infrared spectroscopy (FTIR). In some cases, the spectra show different shapes and in addition, the presence of characteristic signals of other functional groups, indicates that some reactions between the bitumen and the biological component occurred (Fini et al., 2011). In others the positions of the functional groups related to the bitumen were unaltered. So in the latter, it can be seen that the bitumen and the biological component are miscible and there were no chemical reactions (Ingrassia et al., 2019; Zhang et al., 2022a).

Several studies have been conducted on the development of bio-binders obtained by mixing bitumen and biological components in order to develop extended and modified classes of bituminous binders.

As regards alternative binders, however, there are not many scientific works that attest to the possible development from biomaterials, but research is continuous updated in minimizing the carbon content.

6. Rheo-mechanical properties of bio-binders

The bio-materials used in the development of bio-binders are in most cases obtained through TCC treatments. Bio-char and bio-oils are the main products. These, mixed with bitumen for bio-binder formulations, give the final binder blend performance improvements.

6.1. Rheological properties of bio-binders with low amount of bio-materials

The development of bio-based modified binders, with low percentages of replacement (about 10 wt%) of the bituminous component with biological materials, can be considered as the basis for more marked fossil replacements. In the case of bio-chars, their use in the development of bio-binders is mainly for bio-based modified ones. In literature, some studies report formulations developed with bio-char having a percentage of biological components ranging from 5 wt%-20 wt%. From the analyses conducted through the characterization of the binder mixtures, it was observed an overall improvement of binder properties thanks to the presence of the biological source. The final bio-binders with bio-char were found more viscous than the traditional bitumen. In addition to this, studies have reported an increase in stiffness, resistance to deformation, and wear, and in some cases having an antioxidant property. However, the bio-char was also reported to have a negative effect on the performance at low temperatures (Dong et al., 2020; Zhao et al., 2014b; Zhou et al., 2020).

In case the biological component is a viscous liquid, it is essential to understand the physical properties that should be met by binders to be used in the paving industry. Bio-oils are chemically complex, and it is challenging to perform chemical analysis or determine their performance. Density and viscosity are the most widely considered physical properties. The density is higher than the raw material from which they are obtained; instead, the viscosity is a factor that depends on the water content (14 wt%-33 wt%) and the presence of light compounds (Raouf et al., 2010).

Unlike bio-char, the addition of bio-oil showed a negative action on the final mixture (Fig. 4) due to its softening effect. In fact, studies report that substitutions of the fossil component with bio-oils with percentages ranging from 2 wt% to 15 wt% influence viscosity. The action of the bio-oils within the binder mixture leads to a change in the performance grade (PG) index. There is a reduction in performance at high temperatures, so the bio-binders are more prone to rutting. Conversely, the lower PG value decreases so the bio-binders appear to have greater resistance to cracking. Technically, there is a reduction in the softening point (°C) and an increase in the penetration value (dmm) (Table 3) (Fini et al., 2012; Gondim et al., 2016; Kowalski et al., 2017; Singh-Ackbarali et al., 2017; Sun et al., 2016).

Figure 4

Figure 4| Bio-oil (wt%) | High-temperature property (°C) | Low-temperature property (°C) |

|---|---|---|

| 0 | 61.7 | -29.9 |

| 5 | 56.3 | -31.3 |

| 8 | 51.8 | -33.3 |

| 10 | 48.9 | -34.2 |

| 15 | 44.7 | -35.8 |

Furthermore, these characteristics can also be observed through the construction of master curves, if the bio-binders show simple thermo-rheological behaviour. In fact, a reduction in the complex modulus G* is observed as the biological component increases compared to bitumen (Gong et al., 2016; Lei et al., 2017). The reduction of the complex modulus can be counteracted through the addition of traditional polymeric materials (i.e., SBS). Other than these, polymers of natural origin such as PLA and lignin also find their use for the above purpose (Gong et al., 2016; Ingrassia et al., 2019; Kowalski et al., 2016; Raouf and Williams, 2010a; Zhang et al., 2017).

6.2. Rheological properties of binders with high amounts of bio-materials

The use of plant-based biomasses to replace fossil constituents is commonly adopted by researchers developing bio-binders with a significant quantity of bitumen replacement. Given the chemical compatibility of the bio-oils and the standard paving bitumen, in terms of composition, the bitumen replacement may exceed the 25 wt%.

The addition of bio-oils from vegetal biomasses usually varies the complex shear modulus, G*. In fact, in the case of bio-binders, the value of G* at high frequencies and/or low temperatures is greater than the targeted value of standard bitumen; vice versa, at low frequencies and/or high temperatures the value of G* is lower than that of bitumen (Barzegari and Solaimanian, 2020; Gaudenzi et al., 2022; Yang et al., 2014). Nevertheless, the observed trends of different bio-binders from rheological viewpoint are not always the same. Rheological studies showed that the addition of bio-oils to bitumen improved the properties of the final binder. In particular, bio-oils obtained from vegetal biomasses (e.g., waste wood) increased high-temperature performance and viscoelastic properties (Raouf and Williams, 2010a; Yang and Suciptan, 2016). However, at low temperatures, these properties are not affected by any benefit using these types of bio-oils. Other rheological studies on bio-binders developed with swine manure and waste cooking oil do not improve the performance of the bio-binder at high temperatures, but the rheological performances benefit at low temperatures (Fini et al., 2011; Onochie et al., 2013; Sun et al., 2016). These inconsistencies are given by the different biomasses that have been used, and hence, their chemical composition. On this basis, the bio-binders made from raw materials such as switchgrass, pinewood and oakwood have differing values in terms of PG. The PG values of the bio-binder obtained with switchgrass bio-oils are lower than the bio-binders obtained with pinewood and oakwood bio-oils. The reason of the higher PG value for the other samples can be ascribed to the more solid chemical structure of pinewood and oakwood and a higher lignin content (Raouf and Williams, 2010b; Zhang et al., 2022b; Zhao et al., 2014b). For this reason, many researches are being developed in search of an evaluation system that allows to characterization of bio-binders of different nature (Zhang et al., 2022a).

Other materials of biological origin that show appreciable performance when converted to develop binders are algae. In fact, their master curves, constructed through rheological tests, appreciably describe those of pure bitumen at high frequencies (and/or at low temperatures) (Dhasmana et al., 2015; Geantet et al., 2022).

When it comes to the rheological properties of bonding materials, including bio-binders, it is important to make some clarifications. For example, when the replacement of fossil constituents is small, in some countries such as the United States, strategic highway research program (SHRP) regulations continue to be followed (Kennedy et al., 1994). If the degree of substitution within the binder material is higher, the principle of time temperature superposition (TTSP) is not longer valid and the frequency sweep tests for the construction of master curves cannot be applied as for the neat bitumen. Indeed, rheological tests conducted on binders with high percentages of the biological fraction show non-compliant results. Therefore, on this basis, for bio-binders, it is not possible to define a simple thermo-rheological behavior, so the TTSP is not valid (Airey et al., 2016; Yang and You, 2015).

6.3. Aging tendency of bio-binders

Another fundamental aspect that must be considered is the long-term performances of bio-binders is their tendency to age. In fact, due to their nature, bio-materials are very susceptible to aging phenomenon. The elementary analysis highlights the chemical structure of these bio-products showing their greater amount of heteroatoms with oxygen than that available in neat bitumen. In fact, in these conditions the light fractions will be displaced and the oxygen content of the bio-binder is greater in respect to standard bitumen. The aging process and therefore the further removal of the light fractions, leads to an increase in the stiffness of the material. This behavior is more evident when the biological component of the bio-binder formulation comes from plant biomass, such as wood waste. On the contrary, studies conducted on bio-binders developed with bio-oils derived from animal waste show a reduced susceptibility to aging (Fini et al., 2015). These changes are detected through comparison with bitumen. In fact, both at low frequencies (and/or high temperatures) and at high frequencies (and/or low temperatures), the behavior closely resembles that of bitumen, despite the reduction in fossil fraction (Barzegari and Solaimanian, 2020; Dhasmana et al., 2015; Ingrassia et al., 2019). In the literature, there are relatively few studies on the aging tendency of bio-binders, indicating a need for further investigation

6.4. Mechanical properties of paving materials with bio-binders

The mechanical behaviour of the paving bio-concrete should be fully characterized in order to assess the feasibility of using the innovative bio-based binders. However, the mix design, production and characterization of the bituminous mixtures made with bio-binders in respect to traditional ones may represent some uncertainties since there are no widely-known protocols/guidelines and the existing experiences are limited. Depending on the type of adopted bio-binder (i.e., the nature of the starting biomass and the production process), the behaviour of bio-concrete may be unchanged or improved if compared to the traditional ones. Macro properties such as workability and compaction, showed improvements due to the presence of the bio-material. This is followed by a reduction in the laying temperature of the mixture of about 20 °C-30 °C (Ingrassia et al., 2019; Kowalski et al., 2017; Su et al., 2018; Zhang et al., 2022b). Several studies have shown that the presence of biological material affects the properties of the mixture. Fatigue improvements have been observed, but also others advantages related to cracking at low temperatures; conversely, a deterioration related to rutting resistance was observed (Cooper et al., 2013; Wen et al., 2013).

The assessment of bituminous concrete performances was studied in different conditions. The response at high-temperature was mainly given by dynamic stability tests and resistance tests against rutting. Promising performance grades of asphalt mixes with bio-binders have been demonstrated through dynamic stability. The low softening point value guarantees the best performance of the bituminous mixture at high temperatures. In addition, the high viscosity of bio-oils gives a good adhesion between the binder and aggregates. The phenomenon is also supported by the amount of functional groups containing oxygen that allow making the binder more polar (Ingrassia et al., 2019; Mogawer et al., 2016; Su et al., 2018; Wen et al., 2013; Zhang et al., 2022b).

Regarding the low-temperature behaviour of concrete produced with bio-based binders, the resistance against thermal cracking was assessed by determining the critical cracking temperature. From comparisons with traditional bituminous mixtures, the material of biological origin within the mix increases the critical cracking temperature value of approximately 30%, although this is not always the case. What has been seen from the rheological analyses in terms of performance at high and low temperatures and the dependence on the type of biomass, was also reflected in the mixtures (Su et al., 2018; Zhang et al., 2022a).

Another critical aspect of paving materials is water damage. As for their performance at high and low temperatures, mechanical tests are also carried out for this aspect. The tests often include Marshall and/or wet indirect tensile strength ones. The scientific literature on these types of tests on bituminous mixtures with bio-binders is not wide. Studies report that samples made with a binder containing 50% by weight of bio-extender (obtained from Oakwood and Pinewood) meet the requirements of the Marshall test specifications. Similarly, indirect tensile tests also show higher results than conventional tests (Mogawer et al., 2016; Su et al., 2018; Zhang et al., 2022b).

7. Conclusions

The aim of the present review paper is to summarize the state-of-the-art on binders used in paving materials developed using renewable sources such as biomasses. To date, the term bio-binder is commonly used to refer to any paving binder that includes in its constituent materials a product obtained from a biological and possibly renewable resource. Therefore, a bio-binder can fall into all three binder classes, i.e., modified/fluxed, extended or alternative binders. However, it is important to clearly define and aim to an increase in the bitumen replacement quantity for striving the green transition of the road paving sector. The most used biological products and how they are obtained by specific chemical processes were described. Moreover, the incorporation methods to partially or totally substitute the bituminous fraction of paving binders by means of bio-products and the final performance of bio-based binders and the related paving mixtures with different percentages of bio-materials were analysed and reported. Thanks to the described state of the art, the following conclusions can be drawn.

-

•

Biomass has shown promising results as bitumen replacement. Nevertheless, it is essential to conduct in-depth investigations of the chemical composition of bioproducts and their interaction with bitumen to fully assess their potential use as bitumen substitutes in all classes of road paving binders. These investigations are crucial to understand the feasibility and effectiveness of biomass in reducing the paving industry’s carbon footprint.

-

•

Considering the potential of TCC processes in utilizing biomass as a constituent material for the development of bio-binders for road pavement, further research is needed due to its significant importance and development in this field. Specifically, focusing on the optimization of pyrolysis processes to efficiently produce bio-oils with predominantly carbonyl chemical compositions can facilitate the replacement of fossil fractions in the development of extended bitumen and alternative binders. Although in small quantities (<10 wt%), bio-char, a secondary product of the process, also finds research for the development of bio-binders.

-

•

Given the possible chemical discrepancies between bio-oils and bio-char and bitumen, research should focus on establishing standardized test protocols to accurately assess their effects on binder viscosity and mechanical performance. In addition, exploring the influence of different types and quantities of biological products on rheological properties is essential to optimize the formulations of bio-binders. This systematic approach will help to improve understanding of the behaviour and facilitate the development of sustainable blends with improved performances.

-

•

The development of mixtures for pavement with bio-binders is a relatively unexplored area of research. Therefore, a more in-depth investigation of full paving mixtures is needed to assess the potential use of bio-binders, considering the dependence of performance on bio-products and binder compositions, which directly affect the properties of paving materials. In addition, it is crucial to explore the ageing trend of bio-based products, as understanding their long-term behaviour is essential to assess their durability and suitability for real-scale road construction applications.

The development of bio-based road construction materials is a challenging and emerging topic for the paving sector, mainly due to the different and intrinsic characteristic of the various bio-based sources and their actual availability and production processes. In addition, the overall carbon footprint of the proposed innovative materials must be correctly assessed in order to meet the environmental, economic and social sustainability targets. For instance, the lifecycle environmental and costs analysis should be always performed along with the development of the bio-binders and their paving admixtures.

Declaration of Competing Interest

Cesare Sangiorgi is an editorial board member of Journal of Road Engineering, and Piergiorgio Tataranni is a young academic editor of Journal of Road Engineering, and they were not involved in the editorial review or the decision to publish this article. All authors declare that there are no competing interests.

Acknowledgments

The research is funded by the NEXT GENERATION EU–PNRR project ex D.M. 352/2022. The authors would like to thank ENI S.p.A for supporting this research.

Alessio Musco is a PhD student in the Department of Civil, Chemical, Environmental and Materials Engineering at the Alma Mater Studiorum-University of Bologna, previously served as a research fellow at the same institution, specializing in the study of materials' thermal degradation and the treatment of resultant gases. He earned both his bachelor's and master's degrees in industrial chemistry from the University of Naples “Federico II” in 2019 and 2022, respectively, focusing on products, processes in the chemical industry, and environmental protection. His current research centers on bituminous binders for road pavements, investigating bio-based raw materials to reduce fossil content and enhance sector sustainability.

Giulia Tarsi is a research fellow in the Department of Civil, Chemical, Environmental and Materials Engineering at the Alma Mater Studiorum-University of Bologna. She holds the MSc degree in civil engineering and completed the PhD course at the University of Bologna on the topic of chemical and rheo-mechanical characterizations of extended bitumens and recycled asphalt mixtures with the final aim of reducing the required amount of standard petroleum bitumen in paving materials by using recycled materials and/or by-products. The use of more sustainable materials and low impact solutions are key topics in Dr. Tarsi’s research. She is an active member within national and international associations such as SIIV and RILEM.

Piergiorgio Tataranni is a post-doc research fellow (junior assistant professor-fixed-term) in the Department of Civil, Chemical, Environmental and Materials Engineering at the Alma Mater Studiorum-University of Bologna. Since 2013, his activity in the roads section of the department is focused on themes related to pavement materials and construction technologies for civil infrastructures. His research is mainly centred on the development of innovative and sustainable materials and low impact construction technologies. On these topics, he is author of several scientific publications, his PhD thesis and he participated in Europeans projects as early stage researcher (H2020, REMINE, MSCA-RISE-2014) and scientific manager (SAFERUP! H2020 MSCA ITN-2017).

Ernesto Salzano is a full professor at the Alma Mater Studiorum-University of Bologna. He also directs studies for chemical and process engineering and serves on the academic board for the PhD in future earth, climate change, and societal challenges. Previously, he held the position of associate professor of chemical plant design from 2015 to 2022 at the same university. Prior to his academic roles, he worked as a researcher at the Italian National Research Council (CNR) for two decades, focusing on deflagrative and detonative combustion phenomena, runaway reactions, process safety, and risks to critical infrastructures. His extensive research is evidenced by over 250 publications across scientific journals, conference proceedings, and books.

Cesare Sangiorgi is a full professor at the Alma Mater Studiorum-University of Bologna. He specializes in pavement engineering materials and sustainable construction technologies, prioritizing recycled materials and low-impact solutions. He fosters student engagement through collaborations with esteemed research institutes. Since 2001, he's partnered with the Nottingham Transportation Engineering Centre and expanded collaborations globally. He led SAFERUP!, recruiting 15 early stage researchers in a consortium of 30 for sustainable urban pavement projects. Presently, he coordinates GreeNexUS, a HORIZON EUROPE project promoting urban greening and infrastructure safety. With numerous research agreements nationally and internationally, he actively contributes to professional associations like SIIV, APSE, iSMARTi, and RILEM, and serves on journal boards and conference committees, publishing extensively in pavement engineering.

-

Peer review under responsibility of Chang'an University.

© 2024 The Authors. Publishing services by Elsevier B.V. on behalf of KeAi Communications Co. Ltd.